china slurry pump liner factory

Latest articles

The size of slurry pump impeller must be considered to ensure it holds up against abrasive wear. Slurry pump impellers are generally larger in size when compared to slurry pumps for less abrasive liquids. The more “meat” the impeller has, the better it will hold up to the task of pumping harsh slurry mixtures. Just think of slurry pump impeller as a football team’s offensive line. These players are usually large and slow. Throughout the whole game they are beaten up, over and over again, but expected to withstand the abuse. You wouldn’t want small players in this position, just like you wouldn’t want a small impeller on your slurry pumps.

china slurry pump liner factory...

china slurry pump liner factory 【china slurry pump liner factory】

Read MoreLifetime use

china slurry pump liner factory...

china slurry pump liner factory 【china slurry pump liner factory】

Read MoreTypes of slurry pumps

china slurry pump liner factory...

china slurry pump liner factory 【china slurry pump liner factory】

Read MoreFine-grained sand can be extremely abrasive and typically wears slurry pumps quickly. Characteristics of coarse aggregates that can affect pump performance are size, shape and surface texture, as well as gradual changes in particle size, while fine materials can create excessive friction in the pipe.

china slurry pump liner factory...

china slurry pump liner factory 【china slurry pump liner factory】

Read More- Hydraulic efficiency is as important as the material, as efficiency is related to wear. The swept-back design of the impeller blades minimises the separation of solids from the carrying fluid, resulting in a more uniform flow. This results in a slower wear rate.

china slurry pump liner factory...

china slurry pump liner factory 【china slurry pump liner factory】

Read MoreIn a subsea installation, the slurry pump runs directly in the slurry and does not require a support structure, which means it is flexible and easy to install. If possible, the catch basin should be equipped with sloping walls to allow sediment to slide down into the area directly below the pump inlet. Agitators should be used when the liquid contains large amounts of solids and has a high particle density. Freestanding or side-mounted (submersible) mixers are an excellent choice for resuspended solids, especially if the catch basin is large or does not have sloping walls.

china slurry pump liner factory...

china slurry pump liner factory 【china slurry pump liner factory】

Read MoreVertical Slurry Pump

china slurry pump liner factory...

china slurry pump liner factory 【china slurry pump liner factory】

Read MoreAdvantages of rubber

china slurry pump liner factory...

china slurry pump liner factory 【china slurry pump liner factory】

Read MoreApplications

china slurry pump liner factory...

china slurry pump liner factory 【china slurry pump liner factory】

Read MoreLarger impellers made of more material. This is to compensate for the wear and tear caused by abrasive slurries.

china slurry pump liner factory...

china slurry pump liner factory 【china slurry pump liner factory】

Read More

Popular articles

- >Slurry pump impeller is one of the most important parts of centrifugal slurry pumps. Depending on the application, slurry pump impeller selection is crucial to slurry pump performance. Slurry applications can be especially hard on the impeller of slurry pumps because of their abrasive nature. In order slurry pumps operates efficiently and stand up to the test of time, impeller has to be selected properly for slurry pumps.

- Safety

- The selection of a dredge or >slurry pump can be a challenging process that can be simplified by understanding the main factors behind the smooth operation of a pump. In addition to providing more efficient performance, the right dredge pump requires less maintenance, lower power and a relatively longer life.

- Despite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

- Pumping mud is not as easy as pumping water. Depending on the type of slurry, there are many variables in choosing the right pump for the slurry. There is no formula or set-in-stone answer as to what the best slurry pump design is. You must combine knowledge and application details to select the ideal target=_blank title=Slurry Pump>slurry pump. Let's talk about how slurry pumps differ from standard pumps and how to narrow your choices.

- Slurry pumps are usually larger than standard pumps, have more horsepower and use stronger bearings and shafts. The most common >type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids pass through a standard centrifugal pump.

Latest articles

-

Rubber lined pumps offer many advantages

-

The same point of slurry pump and mud pump

-

Lifetime use

-

Slurry pumps can also simply axially adjust the clearance between the impeller and the adjacent throat casing sealing surface. This helps to maintain pump performance when internal components begin to wear.

-

I hope this short blog has helped to clear up some of the confusion about the seal flush programme. Please always refer to the pump manual for specific details. If there are still questions, welcome to >contact us today.

-

Slurry Pump Impeller Type

Links

6061 6063 - Pocket doors, unlike traditional hinged doors, slide into a wall cavity when opened, thus maximizing space and providing unobstructed access to rooms. This innovative concept wouldn't be possible without the intricate system of tracks and rollers working harmoniously behind the scenes.

- Once you have removed the old wheels, it's time to install the new ones

- Difficult manufacturing process, it takes time to create, expect long lead times (approximately, 6 to 8 weeks).

cast iron wood burning stoves. The intricate designs and decorative details of these stoves add a touch of elegance and sophistication to any living space. Whether placed in a rustic cabin or a modern home, a cast iron wood burning stove can become a focal point of the room and create a warm and inviting atmosphere.

The company takes pride in using the highest quality materials and ensuring that each piece is meticulously crafted to perfection. Their attention to detail and commitment to excellence have earned them a stellar reputation in the industry.

architectural iron company

Thus, this material can withstand high pressure without running its form or dimensions, making it ideal for windows and doors profiles.

3) Type of glass

The procedure may differ slightly based on the door model, but generally, it includes unscrewing the roller assembly from the door frame, detaching the old roller, and attaching the new one in its place The procedure may differ slightly based on the door model, but generally, it includes unscrewing the roller assembly from the door frame, detaching the old roller, and attaching the new one in its place

The procedure may differ slightly based on the door model, but generally, it includes unscrewing the roller assembly from the door frame, detaching the old roller, and attaching the new one in its place The procedure may differ slightly based on the door model, but generally, it includes unscrewing the roller assembly from the door frame, detaching the old roller, and attaching the new one in its place aluminium sliding door roller replacement. Make sure to follow the manufacturer's instructions carefully to avoid damaging the door or the new roller.

aluminium sliding door roller replacement. Make sure to follow the manufacturer's instructions carefully to avoid damaging the door or the new roller.

Steel is created after the addition and subtraction of several natural and man-made compounds.

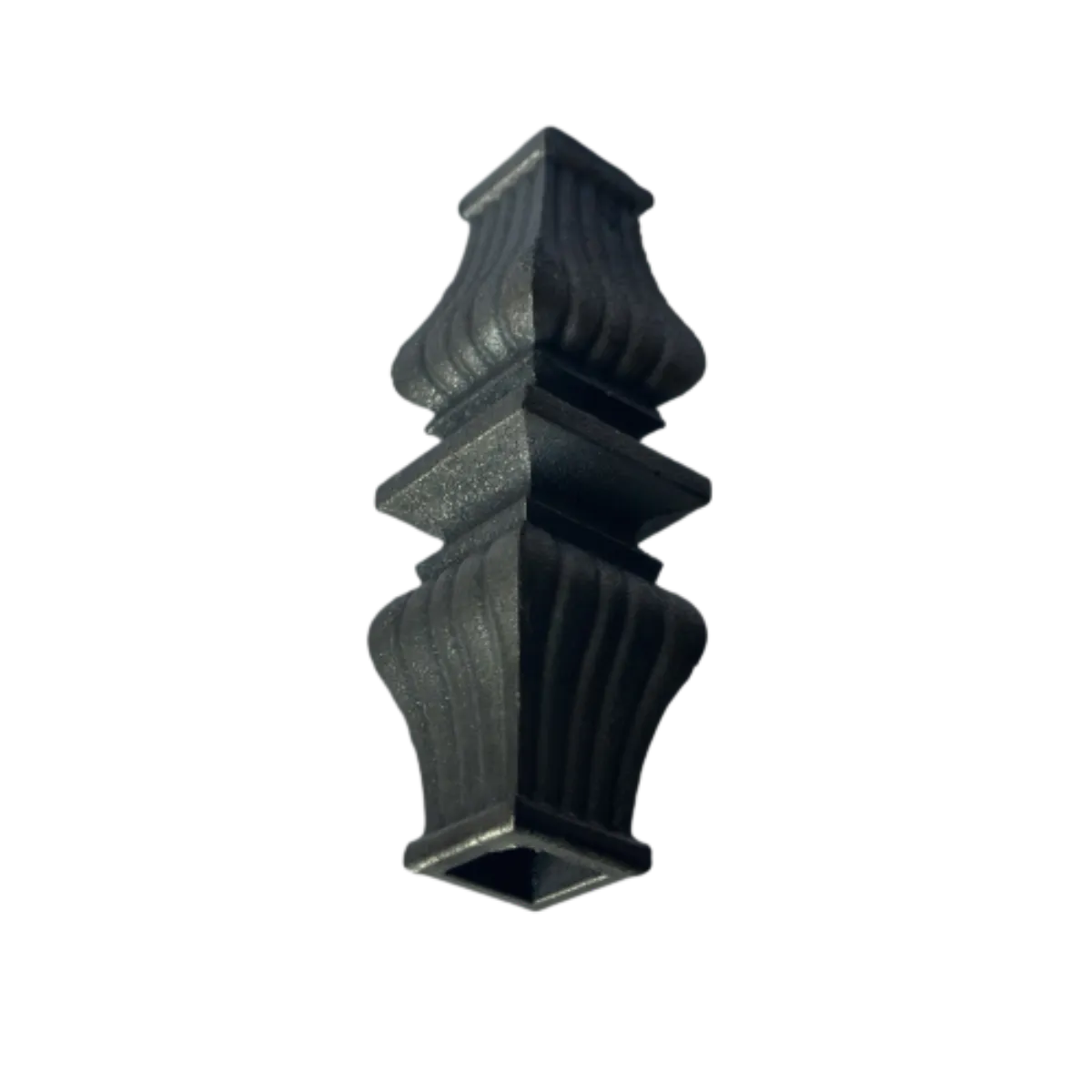

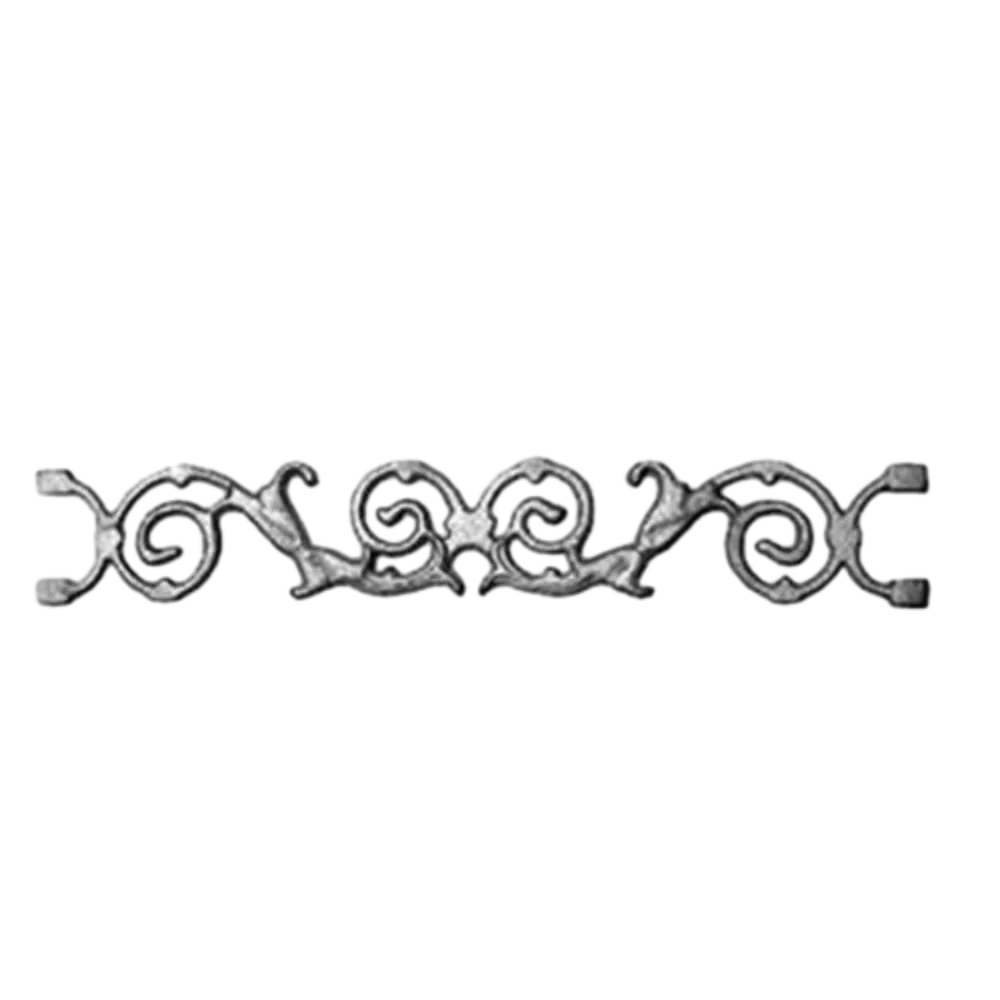

Vertical members, also known as spires, are the vertical pieces of wrought iron that serve as the fence ‘posts’, and in terms of fence construction, pickets are the vertical pieces that make up the centre of a fence panel. These are welded to the rails on a wrought iron fence. Pickets can also be known as balusters, and picket castings are ornamentation attached to a picket for decoration.

document lock box metal. Its sturdy build and secure locking system make it difficult for potential intruders to tamper with or steal its contents. It’s not just about keeping documents safe; it's about peace of mind knowing your most precious assets are well-protected.

document lock box metal. Its sturdy build and secure locking system make it difficult for potential intruders to tamper with or steal its contents. It’s not just about keeping documents safe; it's about peace of mind knowing your most precious assets are well-protected.Another important consideration is the equipment and materials used by the welding service. High-quality welding equipment and materials are essential for achieving strong and durable welds. Additionally, the welding service should follow proper safety protocols to ensure the safety of both the workers and the clients.

wrought iron welding near me

In addition to their security and durability, stainless steel gate lock boxes are also very easy to install and maintain. These boxes are designed to fit neatly onto most gates, providing a seamless and professional appearance. Once installed, they require very little maintenance, giving you hassle-free security for your property.

The use of cast iron dates back to the 18th century, during the industrial revolution, when it became a popular material due to its ability to be molded into intricate designs. The combination of durability and versatility made cast iron the material of choice for many architects and artisans. Ornamental cast iron panels grew in popularity for their ability to create stunning visual focal points in buildings, balconies, gates, and fences.

Iron gates have long been a symbol of grandeur, security, and sophistication, particularly when they serve as the main gate to a property. They not only provide a strong physical barrier but also create an aesthetic appeal that can set the tone for the entire space. The design of a main gate iron gate is a crucial aspect of architectural planning, as it serves as the first impression and a statement of the owner's taste and style.

sliding window roller price. It's a classic dilemma of paying more now for potential savings later. Some may opt for cheaper alternatives, hoping to mitigate initial costs, only to face the consequences of increased maintenance and lower performance down the line.

sliding window roller price. It's a classic dilemma of paying more now for potential savings later. Some may opt for cheaper alternatives, hoping to mitigate initial costs, only to face the consequences of increased maintenance and lower performance down the line.Anodized:7-23 μ , Powder coating: 60-80 μ , Electrophoresis film: 12-25 μ

Key locks are the traditional choice for securing steel boxes. They are easy to use and provide a high level of security when paired with a strong and sturdy key. However, keys can be lost or stolen, which poses a risk to the security of your belongings. For added peace of mind, consider keeping a spare key in a separate location or investing in a lock that allows for key duplication.

steel box lock

aluminum sliding door rollers. Whether you have a traditional sliding door or a more modern glass door, aluminum rollers can provide the smooth operation you need.

Inspect the seals and weatherstripping around your aluminum windows: Regularly inspect the seals and weatherstripping around your aluminum windows for any signs of wear, damage, or gaps. Replace damaged or worn-out seals to maintain proper insulation and energy efficiency. Clean the seals regularly to prevent dirt or debris buildup that can affect their effectiveness.

screen door wheel replacement. Begin by attaching the wheel assembly to the bottom of the screen door, making sure it is aligned with the track. Use the provided mounting screws to secure the assembly in place. Tighten the screws securely, but avoid over-tightening, which can strip the threads.

screen door wheel replacement. Begin by attaching the wheel assembly to the bottom of the screen door, making sure it is aligned with the track. Use the provided mounting screws to secure the assembly in place. Tighten the screws securely, but avoid over-tightening, which can strip the threads.